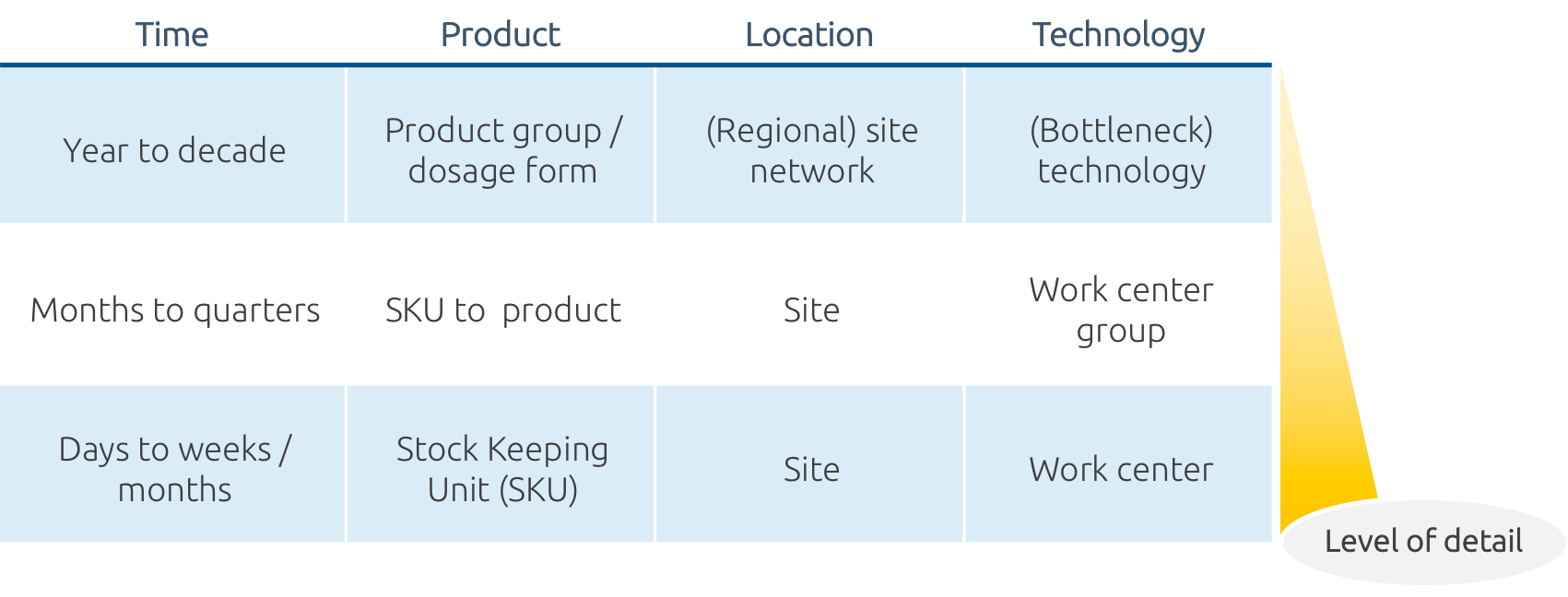

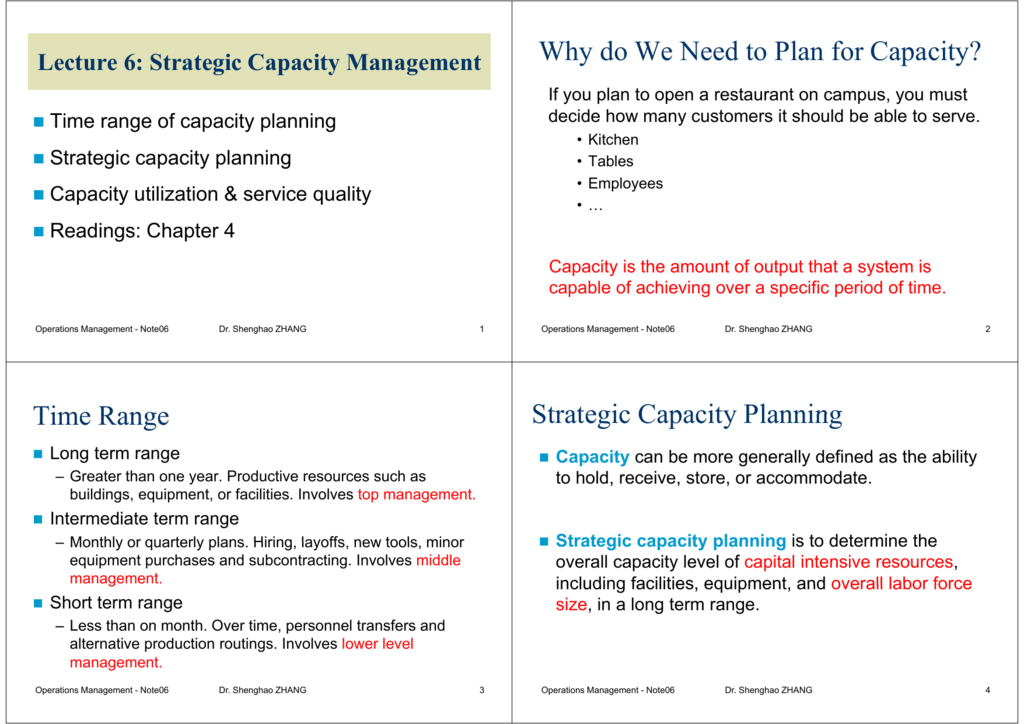

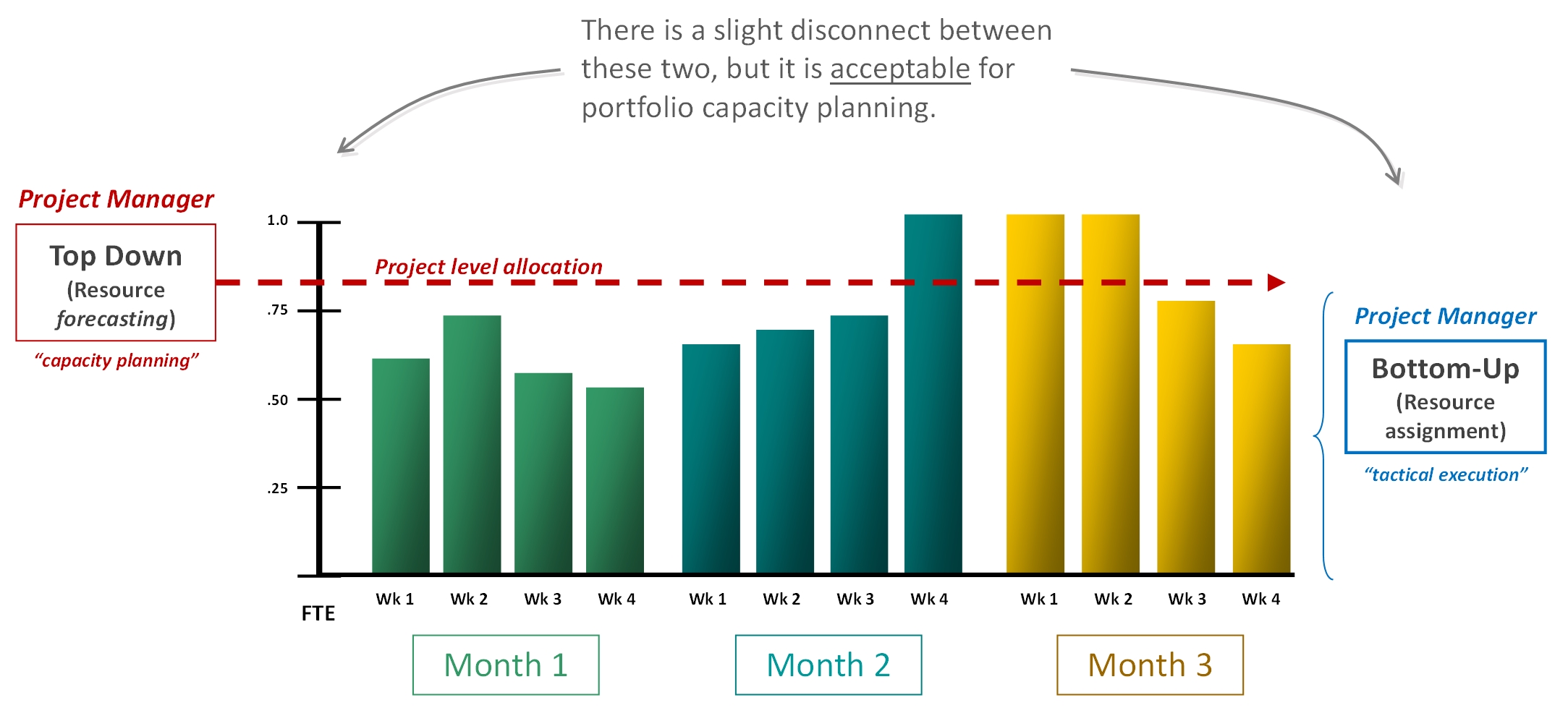

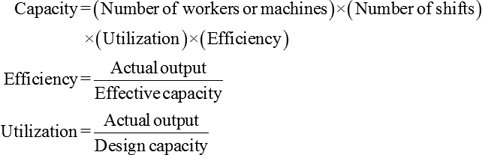

Effective capacity is the maximum amount of work thatLevel capacity strategy The demand for any product is never constant It may change due to various reasons An operations manager has to plan in advance about the demand of the product He or she may have to use some strategies to meet this uneven and everchanging demand pattern These include pure strategies and strategy which uses a combination of various strategies Capacity planning should take place at both the aggregate and the disaggregated level Aggregate capacity planning looks at a longer timeframe – from 2 to 18 months – while disaggregated capacity planning focuses smaller time buckets based on the longer aggregate plan In order to plan capacity, first it must be determined This can be done by measuring your

Capacity Management Maturity Model Helpsystems

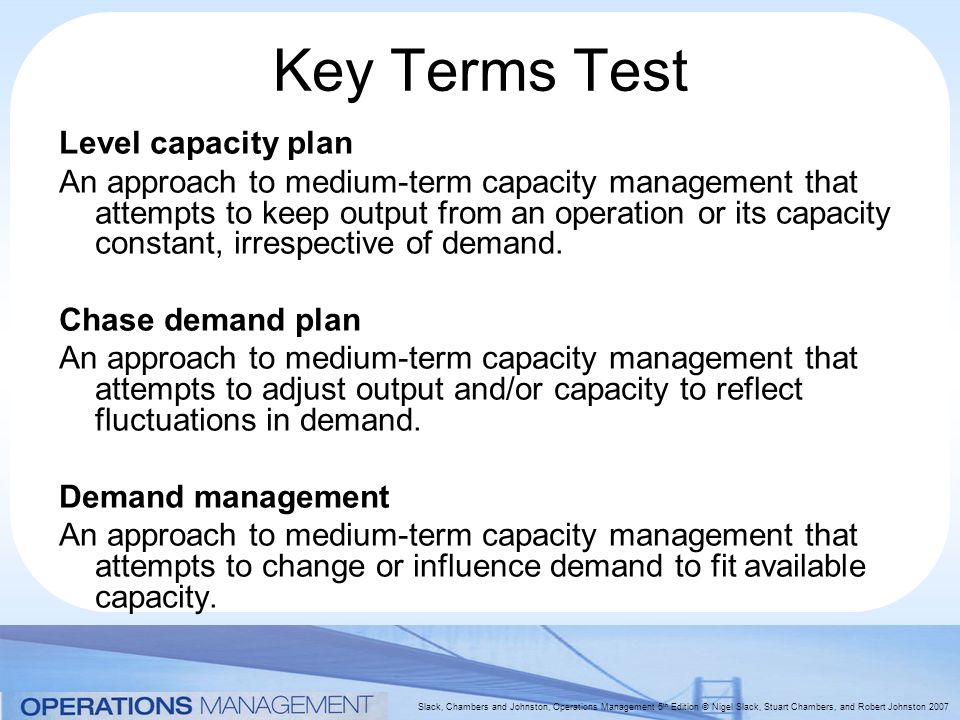

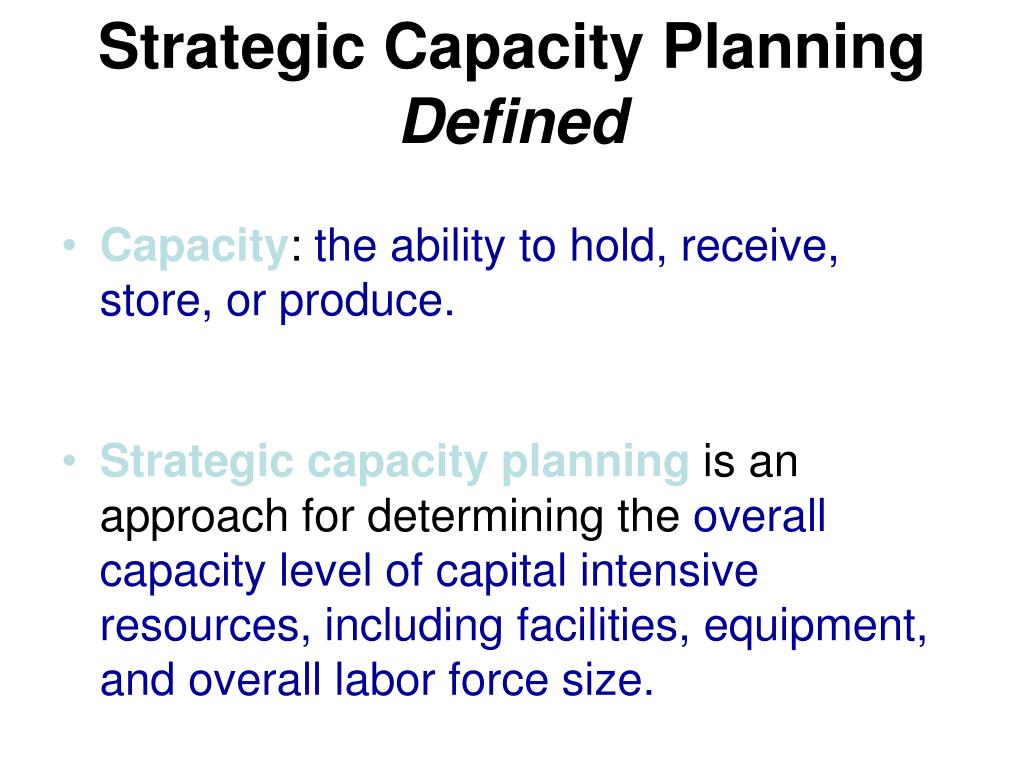

Level capacity planning

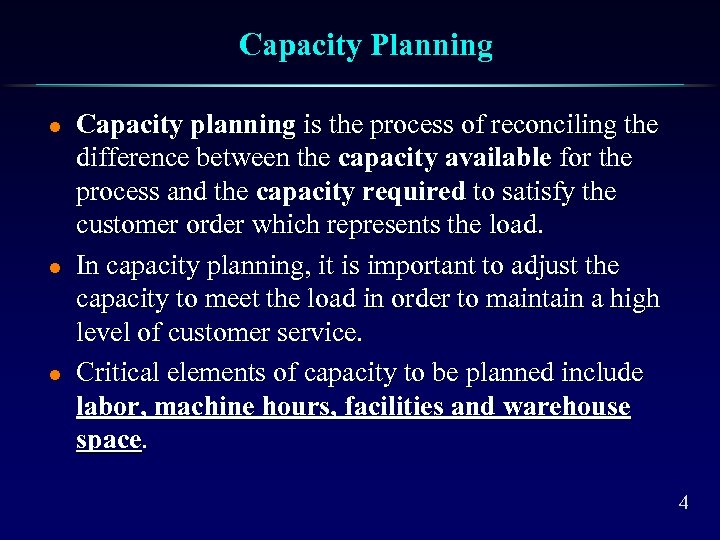

Level capacity planning- Capacity planning is the process of determining the production capacity needed by an organization to meet changing demands for its products now and in the future Background on the Study Commissioned by Planview and conducted by Appleseed Partners, the research features an impressive global response from more than 600 executives from large product and projectParticipatory capacity building A practical toolbox for internal or external facilitators of capacity building in NGOs The tools can be used to assess an organisation's capacity and to plan for strategic and innovative directions for organisational improvement The toolbox is tailored to developing countries, especially in Africa

Capacity Planning Maturity Matrix Blog Planview

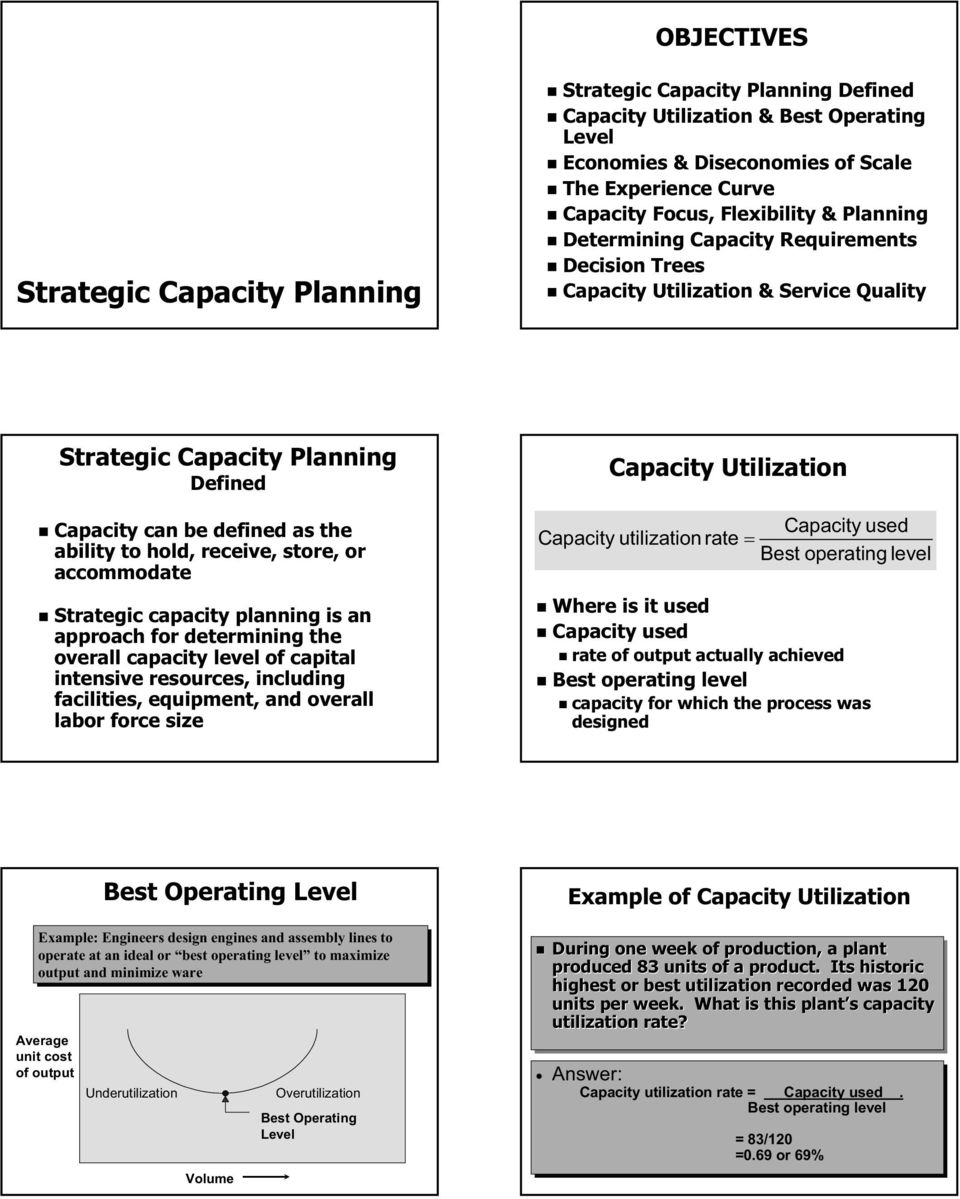

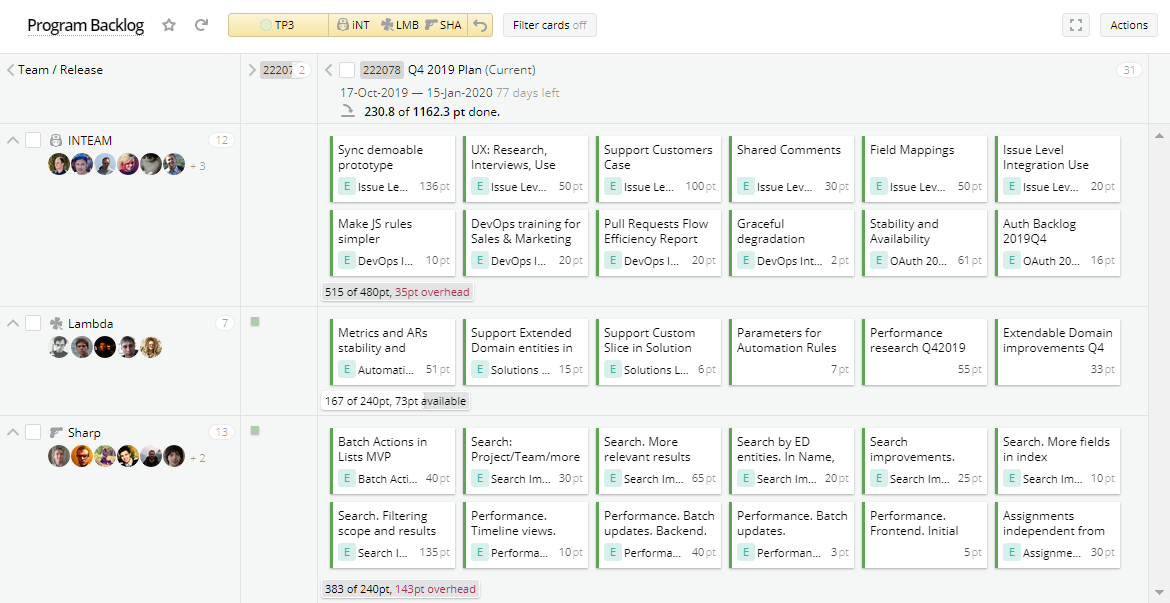

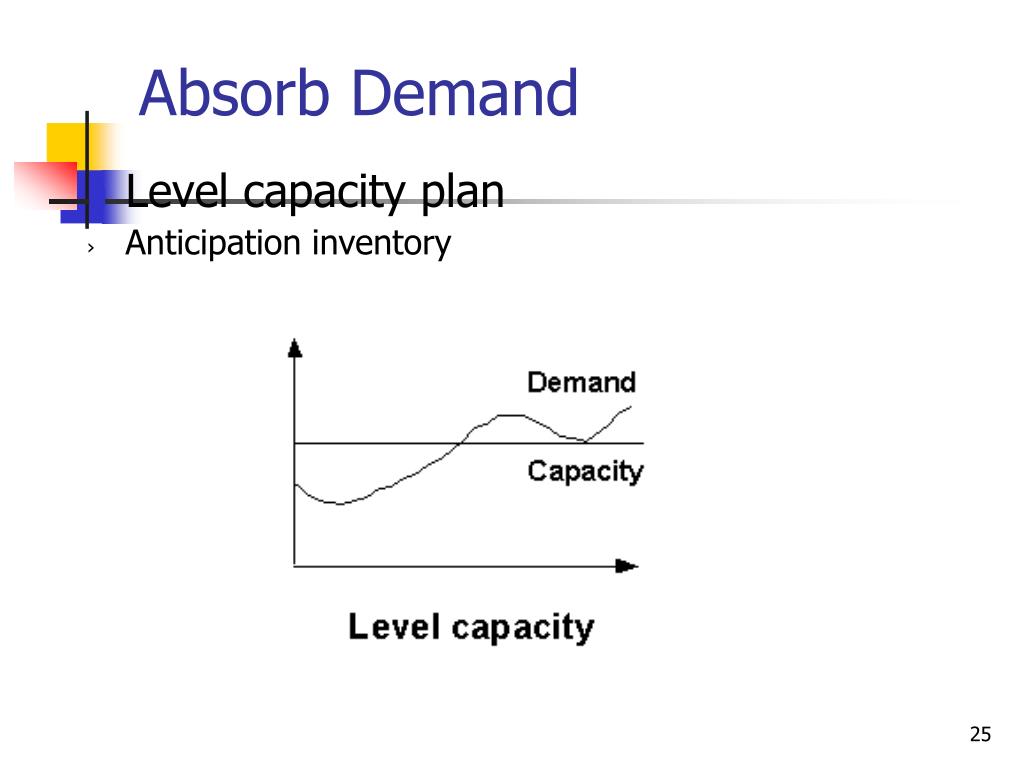

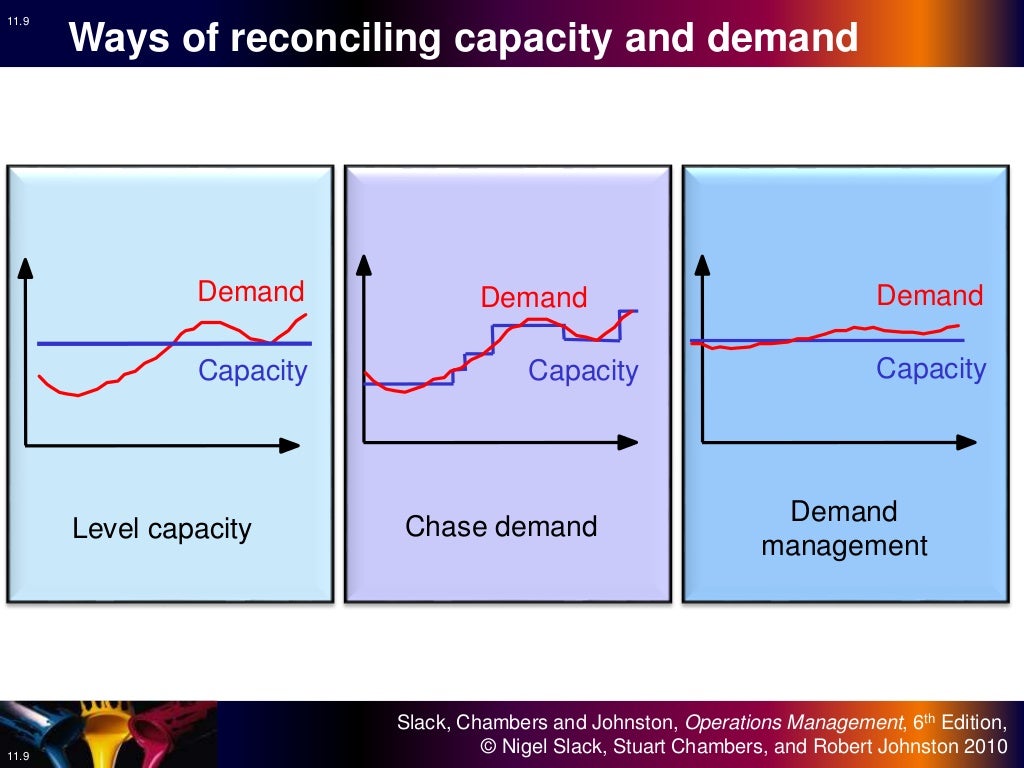

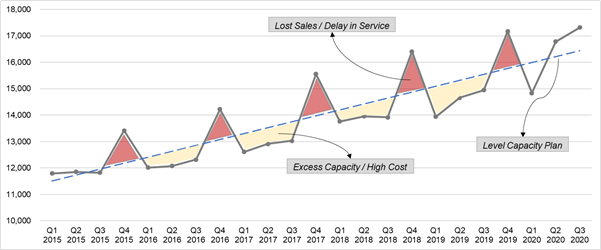

Survey participants were asked what level best describes the Capacity Planning or Resource Management Maturity Level for their organization The following are descriptions that were provided in the survey Level 1 is the lowest level of maturity to Level 5, the highest level of maturity Use these descriptions to assess your organization's maturity level Capacity Planning Maturity LevelsLevel Capacity Plan Definition An approach to mediumterm capacity management that attempts to keep output from an operation or its capacity constant, irrespective of demand Operations Management by Nigel Slack, Alistair BrandonJones, Robert JohnstonFiguring out how we capture and model all of these data to forecast our service levels and determine our true FTE requirements otherwise known as Capacity Planning (CP) – that's my passion I think I am drawn to this discipline because is has proven to be so difficult for the WFM industry to figure out On the surface, it seems pretty strait forward There are four basic pieces

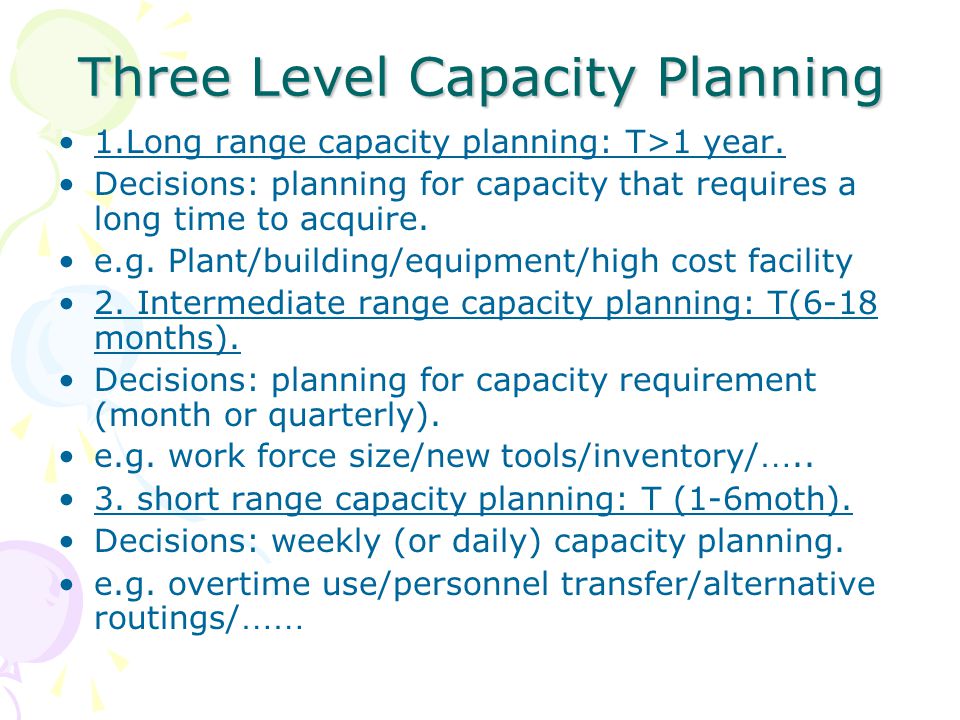

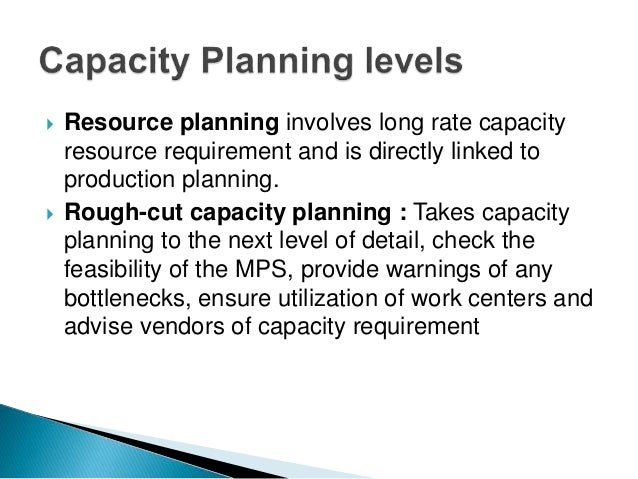

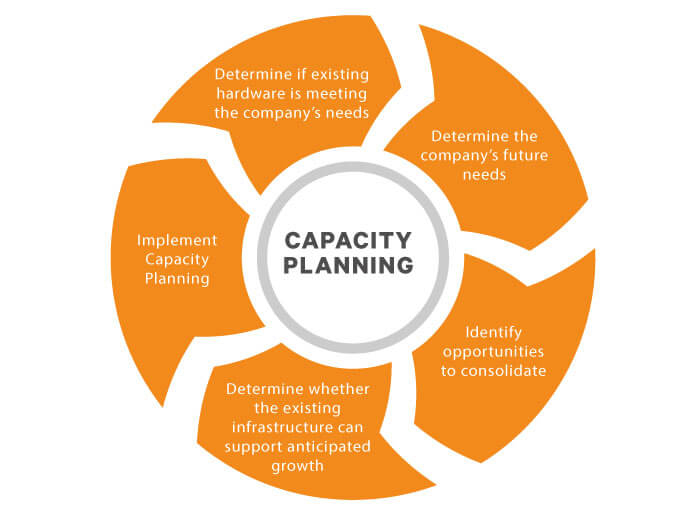

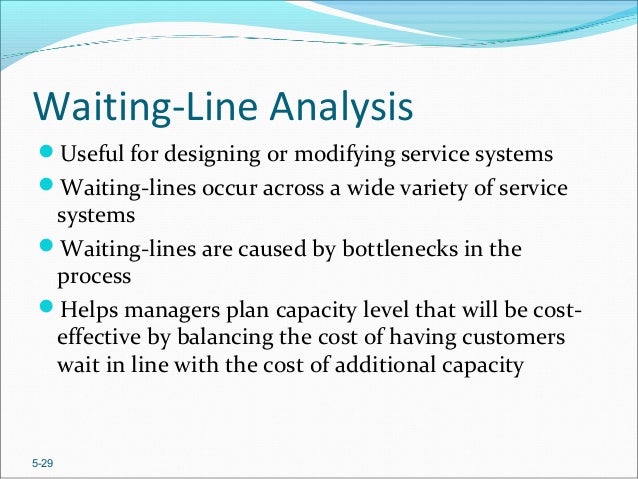

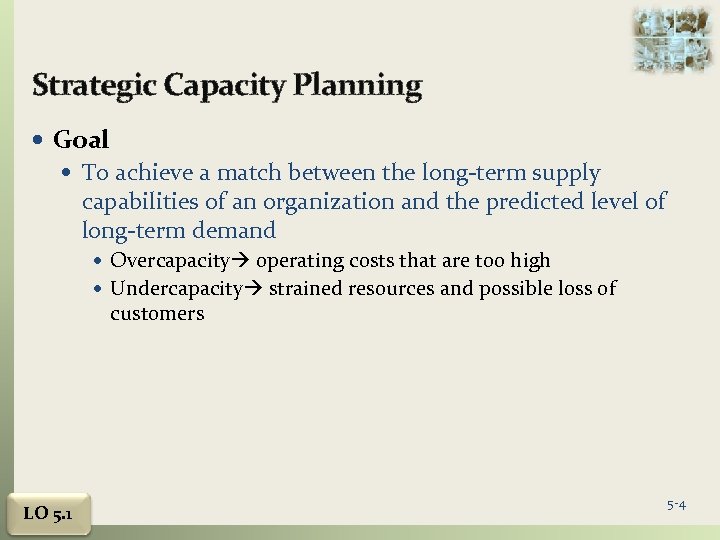

Capacity planning is the process used to determine how much capacity is needed (and when) in order to manufacture greater product or begin production of a new product A number of factors can affect capacity—number of workers, ability of workers, number of machines, waste, scrap, defects, errors, productivity, suppliers, government regulations, and preventive maintenance Capacity planningResource capacity planning isCapacity planning can be difficult at times due to the complex influence of market forces and technology 11 Forecasting Capacity Requirements Longterm capacityneeds require forecasting demand over a time horizon and then converting those forecasts into capacity requirements 12 Shortterm capacityneeds are less concerned with cycles or trends than with seasonal variations

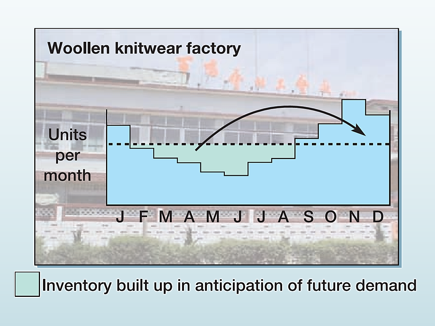

Course Title BUSINESS 6012B0411Y; ANS A level production strategy plans for the same production rate in each time period Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand What is effective capacity?Level capacity strategy The organisation produces or manufactures at a constant rate of output avoiding any changes or fluctuations within customer demand levels This frequently implies stockpiling or higher holdings of inventory while customer demand levels reduce

Capacity Management Objectives Roles Concepts Mitsm

Demand Capacity Planning Jsc

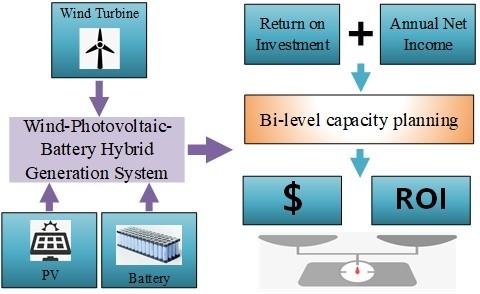

The lower level is a Linear Program (LP) that assigns market demands to production plants Our formulation finds a Stackelberg equilibrium (HV Stackelberg (10)) between the leading producer and the markets The producer makes the first move by deciding on the expansion plan, considering the rationalUploaded By MagistrateMandrill1147 Pages 33 This preview shows page 29 32 out of 33 pages Students who viewed this also studiedThey are Aggregate Demand and Aggregate capacity Aggregate Demand (AD) is the quantitative assessment of the requirement for all goods and services for a specific period of time at a given price level Aggregate capacity is the total amount of capacity required or available to carry out a function It also tells about the 3 best strategies for aggregate planningThey are level strategy,

Capacity Planning What Is Capacity Is The Maximum

Aggregate Capacity Planning Pdf Free Download

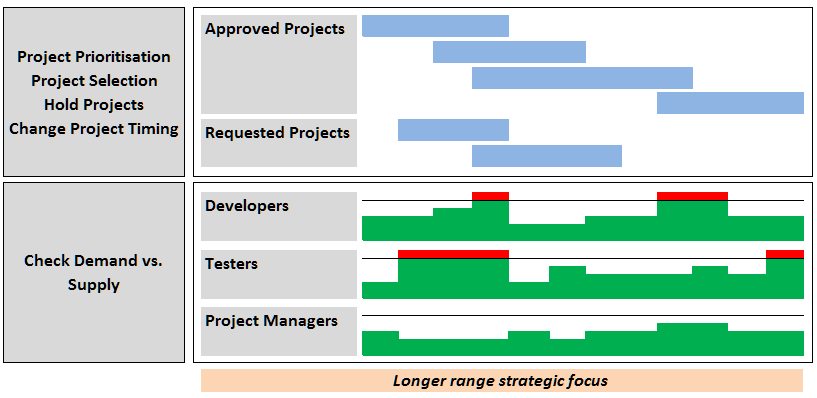

Capacity planning strategy involves the process used to determine the resources manufacturers need to meet the demand for their products or services The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demandCapacity Planning at a Tactical Level in Hospital Departments Agneta Larsson, Anna Fredriksson To cite this version Agneta Larsson, Anna Fredriksson Capacity Planning at a Tactical Level in Hospital Departments IFIP International Conference on Advances in Production Management Systems (APMS), Ajaccio, France pp, /_65Lead Lead capacity planning is the most radical of the capacity planning strategies, as it involves changing capacity in anticipation of market demand Hiring can be a slow process, and lead capacity planning allows organizations to prepare for growing or rapidly evolving markets

Capacity Planning

Best Practices For Resource Capacity Planning Acuity Ppm

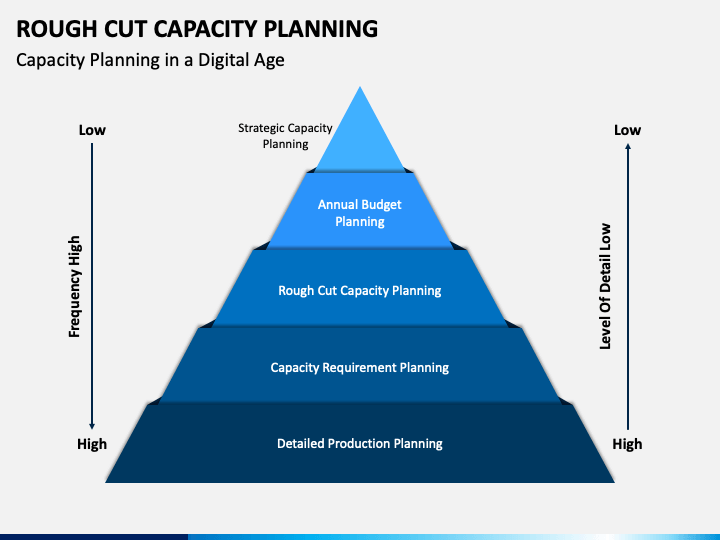

LEVEL STRATEGY FOR CAPACITY PLANNING Many companies experience variable demand for their products This is probably most noticeable in products that have seasonal demand patterns, such as snow blowers or lawn mowers, but demand for other products may vary appreciably throughout the yearBusinesses are in desperate need of an enterpriselevel matured resource capacity planning solution This guide has been designed for businesses to get a comprehensive understanding of enterprise resource demand and capacity planning It will help any company to establish the right processes with the tool 1 What is Resource Capacity Planning?`detailed capacity planning (CRP) at MRP level `both RCCP and CRP are only providing information Production Management 118 Master Production Scheduling MPS Product 1234 A 1000 1000 1000 1000 B 500 500 C 1500 1500 1500 1500 D 600 600 January Week Assembly Inspection 02 B2425 C222 D2524 Bill of capacity (min) ⌧ weekly capacity requirements?

3

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

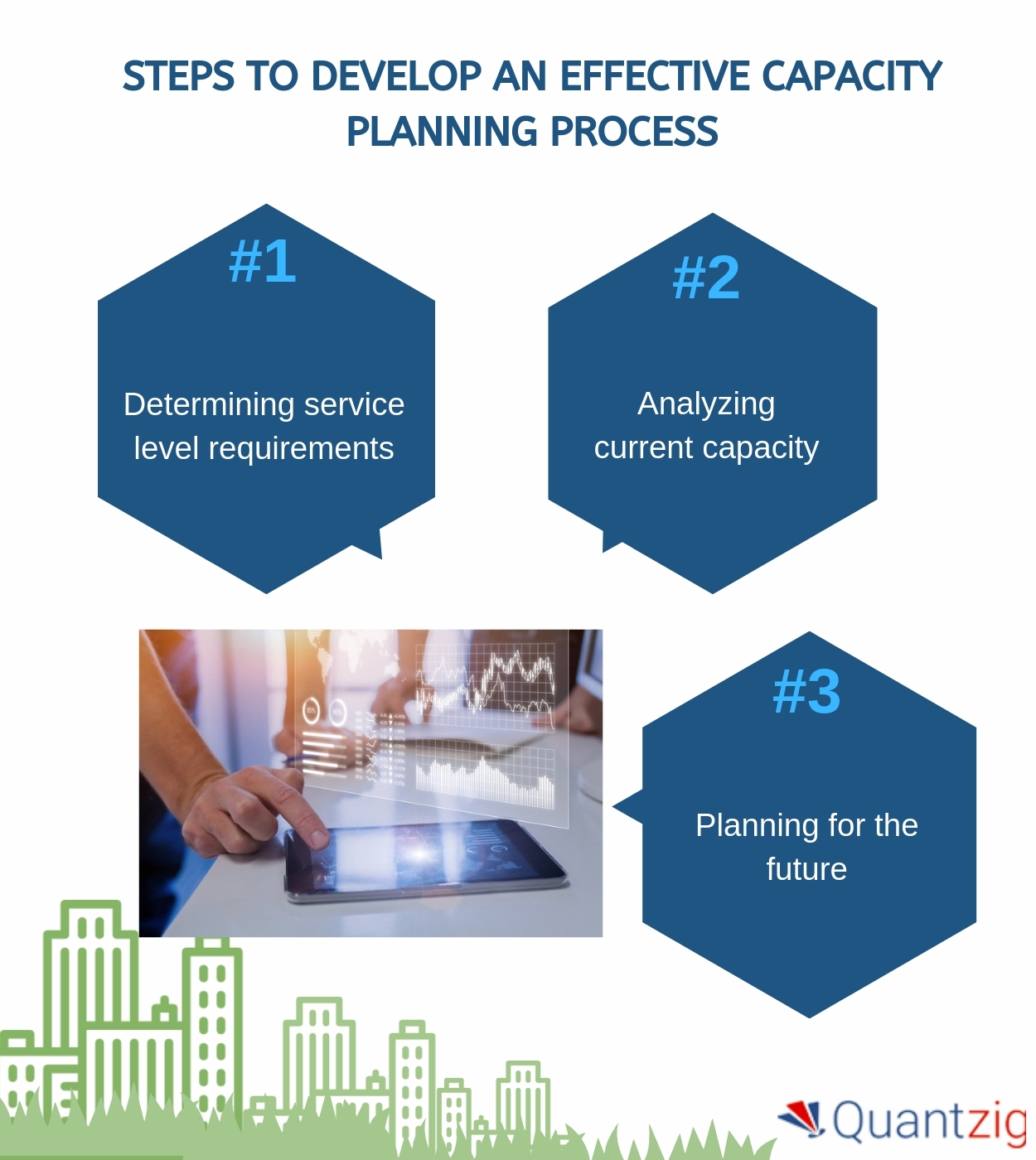

Capacity planning for production is relevant to the product demand/supply concept So, the supply chain managers focus on effective capacity planning in the production process of supply chain management The purpose of production capacity planning tools is to assist the sales team to ensure the company's ability to fulfill customer demand However, a company may produceGoal of Capacity Planning The ultimate goal of capacity planning is to meet the current and future level of the requirement at a minimal wastage The three types of capacity planning based on goal are lead capacity planning, lag strategy planning and match strategy planning Factors Affecting Capacity Planning Effective capacity planning is dependent upon factors likeMonitoring and analysis of cluster capacity are made easy and can be automated as well The Capacity Planning should address current needs and future growth of various resource requirements IT component / resource composite views for both physical and virtual can include servers (OS, CPU, memory, I/O queues), storage, and network requirements

Demand And

Aggregate Planning Mps Capacity Planning Pdf Strategic Management Inventory

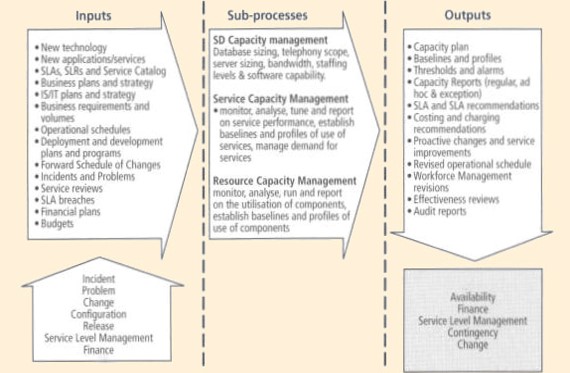

Definition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targets ITIL Process ITIL Service Design Capacity Management Checklist Category ITIL TemplatesThe upper level determines capacity planning decisions using discrete variables; Capacity planning is more high level and helps you determine what and how many resources you need to meet demand Resource planning is more about analyzing resource utilization you use it to takes the number of resources available (as determined by your capacity planning) and allocate them to individual projects

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

High Level Capacity Planning

In our previous blog, we discussed the rational model behind the implementation of LongTerm capacity planning In this blog, we will elaborate more on 'soft' management components like human behavior It plays an essential part in LongTerm capacity planning but is, unfortunately, much harder to get a hold Product capacity planning Product capacity planning ensures that you always have enough raw materials and products needed to complete an order Raw material management is key to product capacity planning, and multi level bill of materials (BOM) are especially important if your products require a lot of product variants and subassembliesCapacity planning, an important element of manufacturing, refers to the process of matching production capacity with sales demand Apart from manufacturing, this discipline is applicable to virtually every endeavor that faces constraints in meeting demand, and it includes service industries, retail and commercial sales, IT, government agencies and many more

Operations Management Lesson 8 Flashcards Quizlet

3

Capacity Management in ITIL Capacity Management in ITIL it is planned to give that IT administrations and IT foundation's capacity is proficient at conveying the decided help level of focuses in a financially savvy and opportune methodology Capacity management ought to be the driving point for all IT execution and limit inconveniences ItCapacity levels for the planning period The second step will be to identify the alternative capacity plans which could be adopted in response to demand fluctuations The third step will be to choose the most appropriate capacity plan for their circumstances2 13 Importance of the issue in the point of capacity controlCapacity Planning Capacity planning is a longterm strategic decision that establishes a firm's overall level of resources It extends over a time horizon long enough to obtain those resourcesusually a year or more for building new facilities or acquiring new businesses Capacity decisions affect product lead times, customer responsiveness, operating costs, and a firm's ability to

How To Develop An Effective Capacity Planning Process Quantzig S Latest Article Unlocks Three Crucial Steps Business Wire

Best Practices For Resource Capacity Planning Acuity Ppm

Capacity planning is high level and strategic To keep your capacity planning simple, you need to analyze your capacity plan at the team or skill level and not by analyzing individual resources Which means for example comparing how many project managers you need for your projects vs how many you currently have1 Level capacity plan 2 Chase demand plan 3 Demand management 8 The idea of a 1 level capacity plan 2 chase demand plan 3 demand School University of Amsterdam; Capacity planning how to reduce FOMO at Clevel?

Long Rang Capacity Planning Ppt Download

Time Range Strategic Capacity Planning

Training is necessary to achieve a level of familiarity that will be necessary to have an effective execution of incident management system c Reaffirm the hospital's participation in a community or regional planning process (ie, Annex G) Ensure this process includes active participation from a broad representation of the county's health, medical agencies and organizations d Review THREE STEPS OF CAPACITY PLANNING 18 Determine Service Level Requirements 19 The first step on the capacity planning process is to categorize the work done by systems and to quantify users' expectation for how the work gets down Define workloads 21 Determine the unit of work 22 Identify service levels for each workload 23Capacity planning is not necessary to predict the future infrastructural needs of the higher institutions in Kogi State Global Journal of Management and Business Research Volume XII Issue XXIII Version I 2 12 earY 64 ©12 Global Journals Inc (US) Capacity Planning and Its Implications on the Infrastructural Development Needs of Some Selected

Capacity Management

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demands It helps identify and reduce inefficiencies associated with either underutilized resources or unmet customer demand and to provide satisfactory service levels in a costefficient manner The planCapacity Planning and Management are explained in this videoThe text was created by an experienced Lean Thinker that gives his point of view on the "Capacit What is Capacity Planning Strategy?

Mcq S Week 7 Capacity Management Chapter 8 Week 7 Capacity Management Which Of The Following Studocu

Capacity Definition In Lte As Operator Level Teletopix Org

Capacity planning is longterm decision that establishes a firm's overall level resources It extends over a time horizon long enough to obtain resources Capacity decisions affect the production lead time, customer responsiveness, operating cost and company ability to compete Inadequate capacity planning can lead to the loss of the customer and business Excess capacity can drain As far as resource planning is concerned BigPicture features both workload and holiday plans (that in BP serve the purpose of vacation plans, too), as well as skillsrelated fields Besides, it is an advanced project management app for Jira that features roadmap, Gantt chart, resources, risks and crossprogram view Oct 21 While capacity planning is for the specific projects the company engages in ProjectManagercom is a Great Capacity Planning Tool Capacity planning requires the right tools to give managers insight into their workforce and how it aligns with their budget

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning Resource Management Why They Differ Teambook

Capacity requirement planning forms part of the operational stage of the planning process and works in conjunction with a manufacturing requirement planning (MRP) system A detailed capacity requirement plan provides an operational level overview for the production cell and assists the operations manager with identifying all of the elements that will be required to deliver

Difference Between Resource Planning And Capacity Planning

Can Capacity Planning Technology Help Plan Labor Budget

Energies Free Full Text Bi Level Capacity Planning Of Wind Pv Battery Hybrid Generation System Considering Return On Investment

Capacity Planning Everything You Need To Know Opensense Labs

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Pdf The Capacity Planning Problem Considering The Procurement Of Bottleneck Machines And Auxiliary Tools Semantic Scholar

1

Capacity Planning And Control Ppt Video Online Download

Capacity Planning Online Presentation

Difference Between Resource Planning And Capacity Planning

Capacity Planning An Overview Sciencedirect Topics

Best Practices For Resource Capacity Planning Acuity Ppm

Capacity Planning Jit And Lean Systems Online Presentation

Feature Based Capacity Planning Targetprocess Enterprise Agility Solution

Capacity Planning 3 Methods How To Implement Them Optimoroute

Team Capacity Planning In The Context Of Service Delivery And Service Level Management Business Process And Improvement

Capacity Management Process Pink Elephant United Kingdom

Long Range Capacity Planning 0 The Hierarchy Of

Capacity Planning Maturity Matrix Blog Planview

Ppt Operations Management Powerpoint Presentation Free Download Id

Production And Operations Management Manufacturing And Services

Capacity Planning And Aggregate Production Planning Ppt Video Online Download

Capacity Planning Kaizen Chronicles

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Pdf A Multi Level Modeling Approach For Simulation Based Capacity Planning And Scheduling Of Aircraft Maintenance Projects Semantic Scholar

Ppt Capacity And Aggregate Planning Powerpoint Presentation Free Download Id

Definition Of Capacity Planning Chegg Com

Ppt Strategic Capacity Planning Defined Powerpoint Presentation Free Download Id

Aggregate Planning Mps Capacity Planning Pdf Strategic Management Inventory

Capacity Planning And Control

Capacity Planning An Overview Sciencedirect Topics

Entries For Thursday 25 October 07 Sergio S Blog

Maintenance Capacity Planning Ppt Video Online Download

Capacity Planning And Control Ppt Download

Rough Cut Capacity Planning Powerpoint Template Ppt Slides Sketchbubble

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Capacity Planning For Project Managers How To Plan Your Team S Time

Aggregate Planning Intermediaterange Capacity Planning Usually Covers A

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

Pdf Aix Frame And Lpar Level Capacity Planning User Case For Online Application Frame And Lpar Level Capacity Planning

Capacity Planning

Capacity Planning 3 Methods How To Implement Them Optimoroute

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Kinaxis Rapidresponse Capacity Planning Constraints 03 29آ Capacity Planning Dashboard Capacity Pdf Document

The Itil Capacity Plan Is Used To Manage The Resources Required To Deliver It Services Capacity Planning How To Plan Change Management

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Naas Playbook Capacity Planning Telecom Infra Project

11 Capacity Planning And Control Operations Management

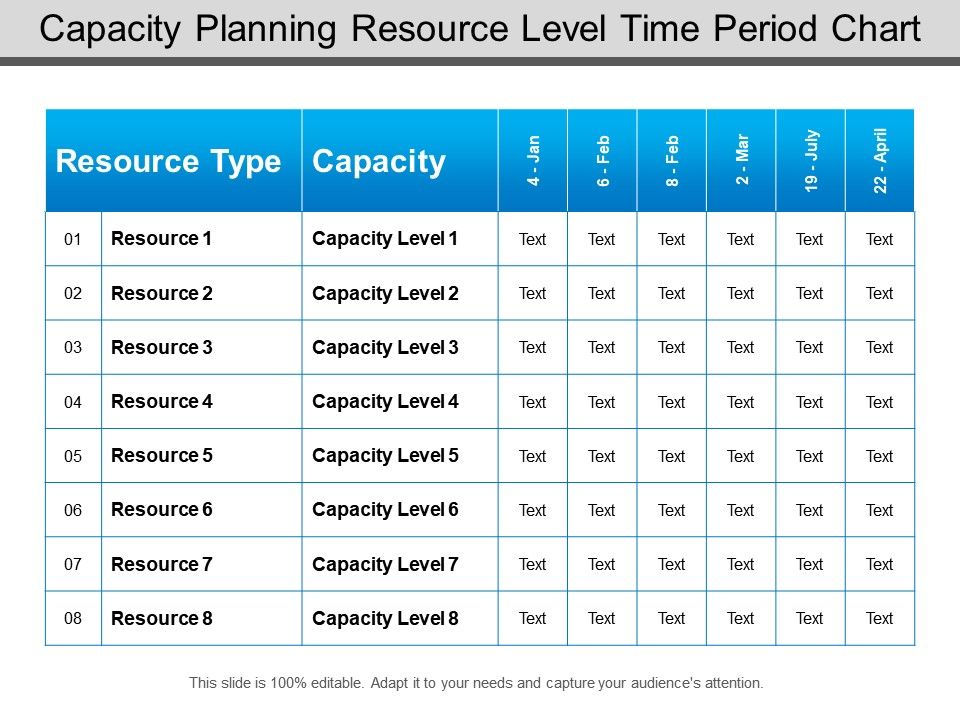

Capacity Planning Resource Level Time Period Chart Powerpoint Presentation Slides Ppt Slides Graphics Sample Ppt Files Template Slide

Chapter 5 Strategic Capacity Planning For Products And

Capacity Planning At Parcel Companies In The Era Of E Commerce By Eyas Al Bakri Medium

Sales And Operations Planning Aggregate Planning Production Planning

What Is Capacity Planning An Introduction Clarizen Success

Sap Pp Capacity Planning

Spot The Difference Capacity Planning Vs Resource Planning In L D Synapse

How To Create Use A Capacity Plan Review Of Optometric Business

Parry Operations Management Managing Capacity Youtube

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

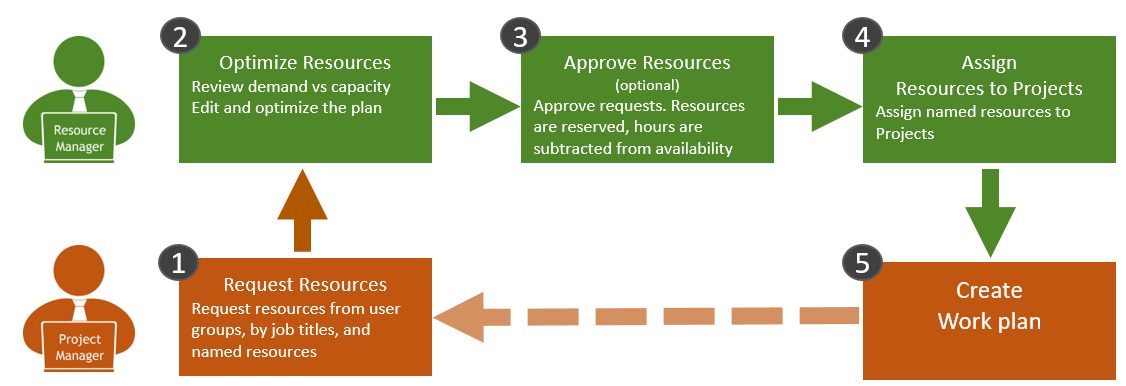

Manage Resource Capacity Planning Scenarios

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

Demand And Capacity Planning In The Emergency Department How To Do It Emergency Medicine Journal

2

Capacity Planning Cloud Computing Questions And Answers Sanfoundry

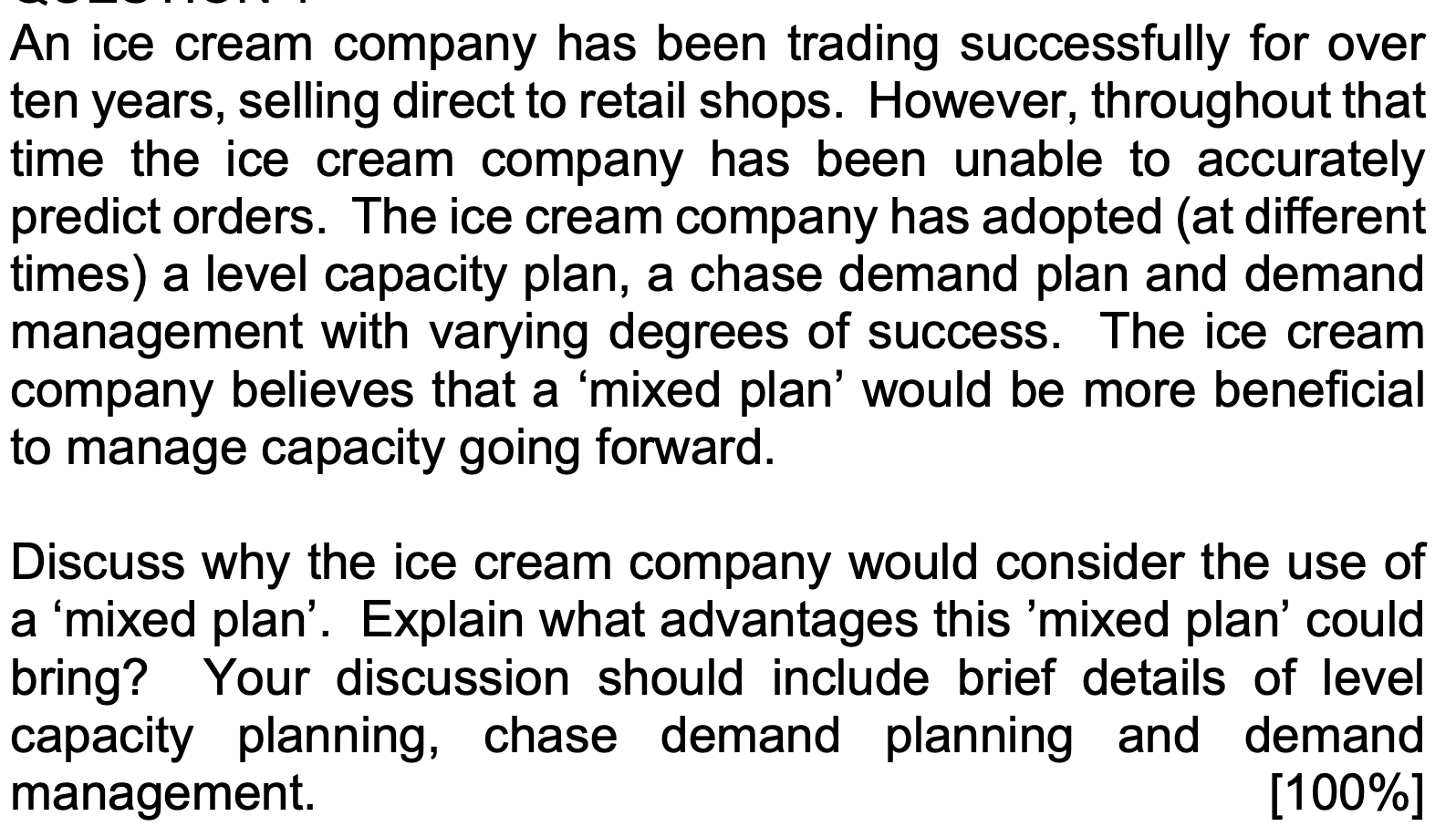

Solved An Ice Cream Company Has Been Trading Successfully Chegg Com

Pdf Lean Capacity Planning Planning For Maximising Customer Value Semantic Scholar

Module 5 Capacity Planning Pdf Inventory Operations Management

Chapter 5 Strategic Capacity Management Lo 5 1

Capacity Management Maturity Model Helpsystems

Operations Management Daniel S Blog

Capacity Planning Purchasing And Supply And Improvement Strategy Of Coca Cola

Capacity Planning Discipline For Data Center Decisions Helpsystems

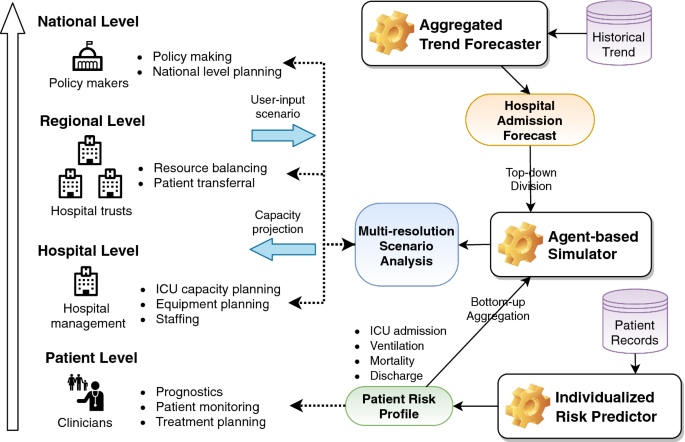

Cpas The Uk S National Machine Learning Based Hospital Capacity Planning System For Covid 19 Springerlink

Capacity Planning For Enterprise Networks An Overview Of

Categorization Of Capacity Planning By The Planning Horizon Download Table

Sap Pp Capacity Planning Cm01 Cm21

Introduction To Capacity Requirement Planning In Sap S 4hana Sap Blogs

Lecture 5 Strategic Capacity Planning For Products And Services Youtube

2

An Integrated Framework For Capacity Planning And Operations Management Download Scientific Diagram

Infrastructure Capacity Planning Tools Market By Technology Advancement And Business Outlook 21 26 The Courier

0 件のコメント:

コメントを投稿